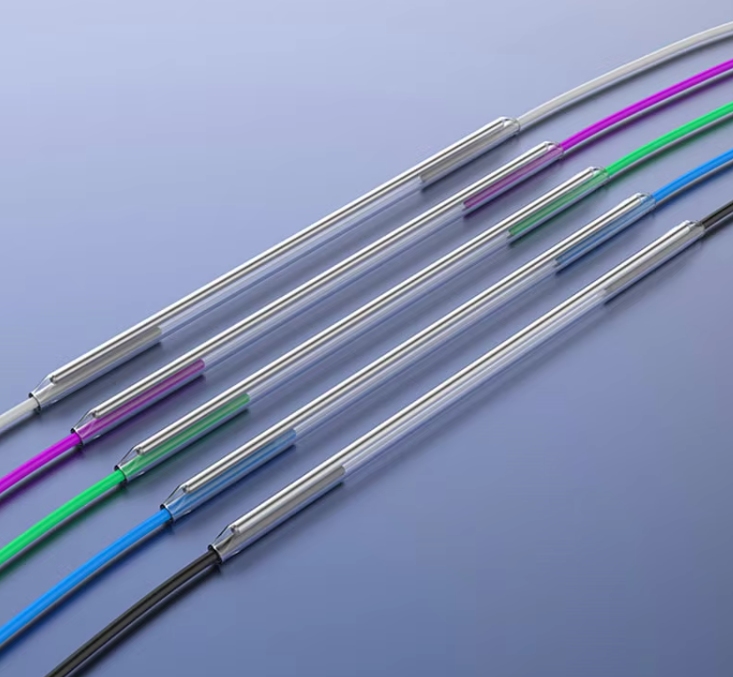

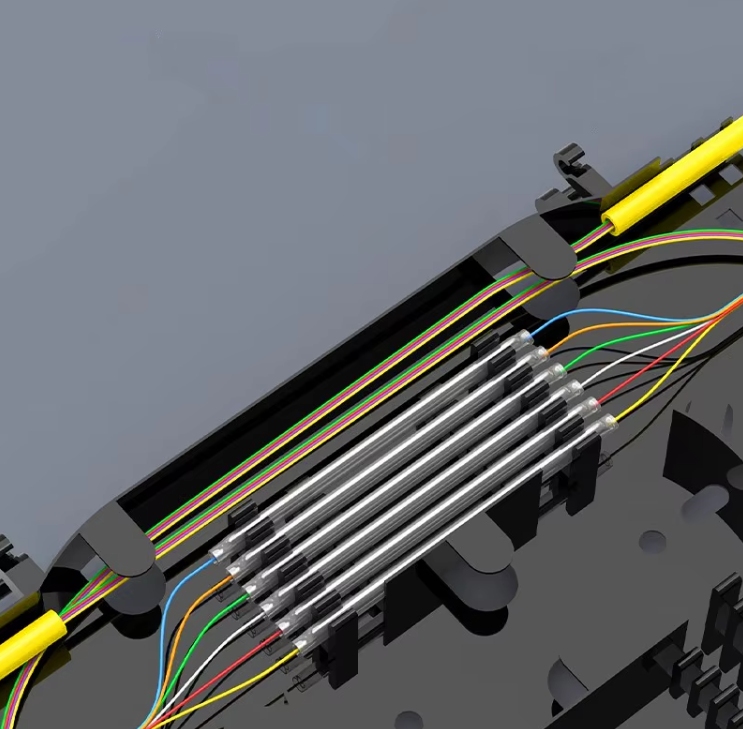

Fiber Optic Splice Protection Sleeve

A specially designed crosslinked Clear Heat Shrinkable tubing, with Clear fusion tubing liner, providing SS304 strength member and protection to fiber optical splices.

Features

Single holed(preshrunk)ends eliminates improper fiber threading

Smooth,deburred stainless steel reinforcing member ends decrease the risk of fiber damage during installation

Extended liner length prevents contact between the fiber and their backbone

Clear sleeve design permits easy centering of splice before heating

Sealing structure makes the splice free from effect of temperature and

humidity from environment

| Properties | Test Method | Typical Data |

| Tensile Strength | ASTM D2671 | ≥18 MPa |

| Ultimate Elongation | ASTM D2671 | 700% |

| Dielectric Strength | IEC 243 | 20 KV/mm |

| Dielectric Constant | IEC 243 | 2.5max |

| Longitudinal Change | ASTM D2671 | 0±5% |

| Density | ISO R1183D | 0.94 g/cm3 |

| Optic Fiber Heat shrink tube(clear) | ||||||

| Type | Stainless steel needle (non-magnetic) | Heat shrink tube | OD after shrinking (mm) | Object Total Length | Packing | |

| Diameter(mm) | Length(mm) | ID(mm) | (mm) | (Pcs/bag) | ||

| Small Optic Fiber protection | 1 | 55 | 0.5 | 2 | 60 | 50 |

| 1 | 45 | 0.5 | 2 | 50 | 50 | |

| 1 | 40 | 0.5 | 2 | 45 | 50 | |

| 1 | 35 | 0.5 | 2 | 40 | 50 | |

| 1 | 30 | 0.5 | 2 | 35 | 50 | |

| 1 | 55 | 1.3 | 2.4 | 60 | 50 | |

| Standard Optic Fiber protection | 1.2 | 55 | 1.3 | 2.5 | 60 | 50 |

| 1.2 | 45 | 1.3 | 2.5 | 50 | 50 | |

| 1.2 | 40 | 1.3 | 2.5 | 45 | 50 | |

| 1.2 | 35 | 1.3 | 2.5 | 40 | 50 | |

| 1.2 | 30 | 1.3 | 2.5 | 35 | 50 | |

| Large Optic Fiber protection | 1.5 | 55 | 1.5 | 3 | 60 | 50 |

| 1.5 | 50 | 1.5 | 3 | 55 | 50 | |

| 1.5 | 45 | 1.5 | 3 | 50 | 50 | |

| 1.5 | 40 | 1.5 | 3 | 45 | 50 | |

| 1.5 | 35 | 1.5 | 3 | 40 | 50 | |

| 1.5 | 30 | 1.5 | 3 | 35 | 50 | |

NO.4007,Peanut U Gu Creative Park , No.57 GuangDa Rd,LongGang Zone, Shenzhen city, China.

NO.4007,Peanut U Gu Creative Park , No.57 GuangDa Rd,LongGang Zone, Shenzhen city, China.

Copyright @ 2026 Shenzhen Sinda Optic Technology Co.,ltd All Rights Reserved.

Copyright @ 2026 Shenzhen Sinda Optic Technology Co.,ltd All Rights Reserved.

Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy