GYTS Steel Tape Layer Loose Tube Outdoor Cable,The fibers, single mode or muti mode , are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath.

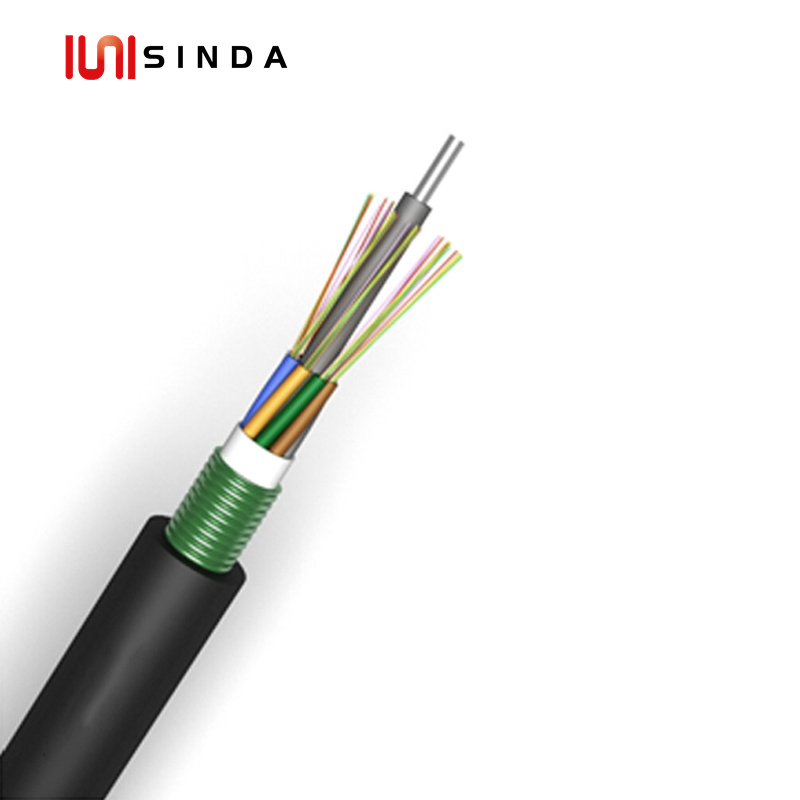

GYTS Steel Tape Layer Loose Tube Outdoor Cable

The fibers, single mode or muti mode , are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath.

Features

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Crush resistance and flexibility

PE sheath protects cable from ultraviolet radiation

The following measures are taken to ensure the cable watertight:

Steel wire used as the central strength member

Loose tube filling compound and 100% cable core filling

PSP enhancing moisture-proof

Cable construction details

| Number of fiber | 2~144core | |||||||

| Moisture Barrier | Water blocking system | |||||||

| Central strength member | Material | Steel wire/FRP/FRP with PE cover | ||||||

| size | 1.5mm~2.0mm | |||||||

| Loose tube | material | PBT | ||||||

| diameter | Ф2.2(outer/inner) | |||||||

| Tube-filling | Tube filling compoun | |||||||

| Armoring | Material | Corrugated steel tape | ||||||

| Outer sheath | material | PE,HDPE | ||||||

| diameter | 1.70±0.2mm | |||||||

Fiber color

| Number of fiber per tube 8cores | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Pink | Aqua | |

| Color 13~24 will be marked with a black tracer. For black color no need marked black tracer, will use nature color instead. | ||||||

Cable Mechanical characteristic

| core | Cable diameter | weight | |||||

| 2 cores to 60 cores | 10.0±0.3mm | 115±5kg/km | |||||

| 72 cores | 10.5±0.3mm | 120±5kg/km | |||||

| 96 cores | 12.5±0.3mm | 180±5kg/km | |||||

| 144 cores | 14.5±0.3mm | 245±5kg/km | |||||

| Min Bending Radius(mm) | Long term | 10D | |||||

| Min Bending | Short term | 20D | |||||

| Radius(mm) | |||||||

| Min allowable | Long term | 600 | |||||

| Tensile Strength(N) | |||||||

| Min allowable | Short term | 1500 | |||||

| Tensile Strength(N) | |||||||

| Crush Load (N/100mm) | Long term | 300 | |||||

| Crush Load (N/100mm) | short term | 1000 | |||||

| Operation | 30 | ||||||

| temperature (℃) | |||||||

| Installation | 40 | ||||||

| temperature(℃) | |||||||

Fiber characteristic

| Fiber style | Unit | SM | SM | MM | MM | MM | |

| G652 | G652D | 50/125 | 62.5/125 | OM3-300 | |||

| condition | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| attenuation | dB/km | ≤ | ≤ | ≤ | ≤3.0/1.0 | ≤3.0/1.0 | |

| 0.36/0.23 | 0.34/0.22 | 3.0/1.0 | ---- | ---- | |||

| Dispresion | 1550nm | Ps/(nm*km) | ---- | ≤18 | ---- | ---- | Dispresion |

| 1625nm | Ps/(nm*km) | ---- | ≤22 | ---- | ---- | ||

| Bandwith | 850nm | MHZ.KM | ---- | ---- | ≧400 | ≧160 | Bandwith |

| 1300nm | MHZ.KM | ---- | ---- | ≧800 | ≧500 | ||

| Zero dispersion wavelength | nm | 1300-1324 | ≧1302, | ---- | ---- | ≧ 1295, | |

| ≤1322 | ≤1320 | ||||||

| Zero dispresion slope | nm | ≤0.092 | ≤0.091 | ---- | ---- | ---- | |

| PMD Maximum Individual Fibr | ≤0.2 | ≤0.2 | ---- | ---- | ≤0.11 | ||

| PMD Design Link Value | Ps(nm2*km) | ≤0.12 | ≤0.08 | ---- | ---- | ---- | |

| Fibre cutoff wavelength λc | nm | ≧ 1180, | ≧1180, | ---- | ---- | ---- | |

| ≤1330 | ≤1330 | ||||||

| Cable sutoff wavelength λcc | nm | ≤1260 | ≤1260 | ---- | ---- | ---- | |

| MFD | 1310nm | um | 9.2+/-0.4 | 9.2+/-0.4 | ---- | ---- | ---- |

| 1550nm | um | 10.4+/-0.8 | 10.4+/-0.8 | ---- | ---- | ---- | |

| Numerical | ---- | ---- | 0.200+/ | 0.275+/-0. | 0.200+/-0 | ||

| Aperture(NA) | -0.015 | 15 | 0.015 | ||||

| Step(mean of bidirectional | dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| measurement) | |||||||

| Irregularities over fiber | dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| length and point | |||||||

| Dicontinuity | |||||||

| Difference backscatter | dB/km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| coefficient | |||||||

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ||||

| Core dimater | um | 50+/-1.0 | 62.5+/-2.5 | 50+/-1.0 | |||

| Cladding diameter | um | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | |

| Coating/chaffinch | um | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| concentrically error | |||||||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding conentricity error | um | ≤0.6 | ≤0.6 | ≤1.5 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ≤4 | ---- | ---- | ---- | |

Applications

Adopted to outdoor distribution;

Suitable for aerial, pipeline laying method;

Long distance and local area network communication.

Packing Info

| Description | HS code | Qty/carton | Wooden roll SIZE | Total G.W(kg) |

| 12C GYTS | 8544700000 | 2000M/ROLL | 80*80*70cm | 200 |

NO.4007,Peanut U Gu Creative Park , No.57 GuangDa Rd,LongGang Zone, Shenzhen city, China.

NO.4007,Peanut U Gu Creative Park , No.57 GuangDa Rd,LongGang Zone, Shenzhen city, China.

Copyright @ 2026 Shenzhen Sinda Optic Technology Co.,ltd All Rights Reserved.

Copyright @ 2026 Shenzhen Sinda Optic Technology Co.,ltd All Rights Reserved.

Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy